Caterpillar has released new bolt-together buckets for underground loaders that can lower assembly and transportation costs as well as reduce downtime on machines.

Offering the same strength and durability as standard buckets, the Cat bolt-together buckets for Cat load haul dump (LHD) does not require skilled maintenance operators for underground welding, resulting in a reduced safety risk. The design allows for efficient underground assembly, where the loader is working, to cut replacement time and lead to lower machine downtime and higher productivity.

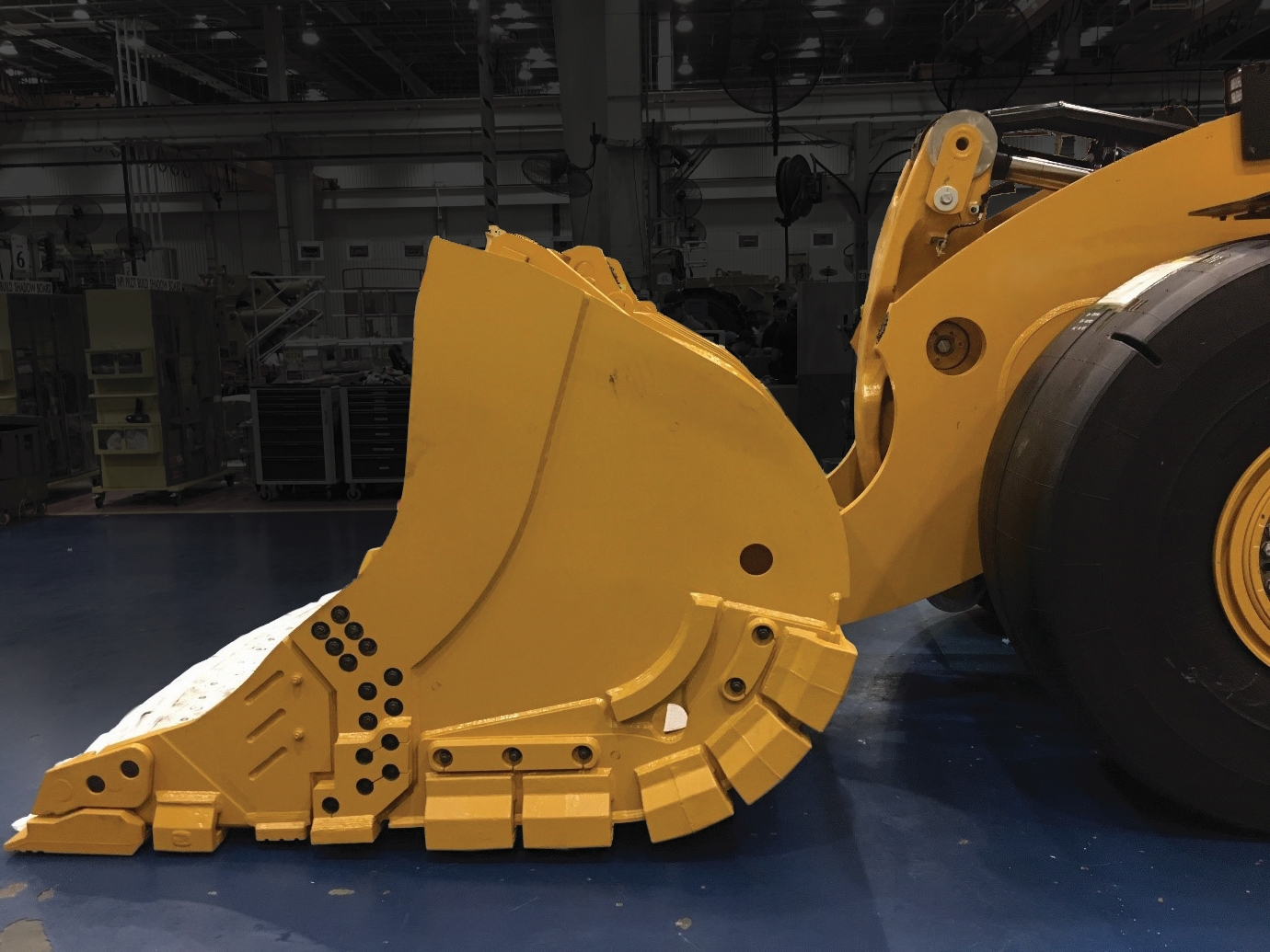

Optimized for moving abrasive underground materials, the new bucket design includes improved material thickness for increased strength and a rigid bucket assembly to aid in easier edge installation and removal. High-grade, 400 BHN materials used for bucket assembly components and high-grade wear protection ground engagement tools (GET) on the removable shroud assembly deliver a long bucket service life for better cost saving and productivity. With proper GET selection and management, the Cat bolt-together bucket is designed to last through the first machine overhaul period to reduce replacement downtime.

Modular in design for quick installation and removal, the numerous Cat GET available for the new bolt-together buckets include three edge options – bolt-on half arrow (BOHA), modular weld-on and Durilock – shroud segments, and rock guard to deliver reduced downtime and accelerated repair.

The new bolt-together bucket is available in a range of capacities from 5.3 m3 (6.9 yd.3) to 7.5 m3 (9.8 yd.3), specially designed for the Cat R1600H, R1700G, R1700 and R1700 XE LHD models. They are built in the same factory and go through the same stringent quality control process as Cat equipment and are supported by the global Cat dealer network.

Source: Caterpillar